A New Gold Standard for Flexible Electronics

A New Gold Standard for Flexible Electronics

April 7, 2014

Business & Management, Nanotechnology, Robotics & High-Tech

Haaretz — Thanks to a cheap and eco-friendly process developed in Israel, roll-up screens and the like on your next smart device could be made of self-assembling gold.

The field of “flexible electronics” is reshaping our world, contributing to cutting-edge technologies like solar panels, “e-newspapers” and Google Glass. Whereas traditional electronics are locked in two dimensions, flexible ones venture into 3-D, bending the limits of what technology can do.

But flexible electronics still rely on old production methods and materials, which tend to be expensive and polluting. Now, Prof. Raz Jelinek, of BGU’s Department of Chemistry and Ilse Katz Institute for Nanoscale Science and Technology, has developed a simple process that uses gold to create flexible electronics much more cheaply and cleanly.

The findings, published in various journals in the past several months, could change the way flexible electronic devices – with circuits that can flex and bend – are manufactured.

Google Glass is one of the many devices that Prof. Jelinek’s technology could help produce. Photo: Dezeen

“I found that a little-known molecule can be adapted to produce transparent gold patterns with nanoscale features,” says Prof. Jelinek. “The process doesn’t require multi-million-dollar machines or leave behind toxic chemicals, and it works on the flexible materials that are going into the latest smart devices.”

The research was partly funded by the Israeli taxpayer – through the Ministry of Science and the Economy Ministry’s Office of the Chief Scientist.

Flexible electronics are a recent extension of conventional electronic technologies. Even more recently, nanotechnology has helped flexible electronics get smaller, suppler and, when necessary, transparent.

Among many other applications, flexible electronics with nano-sized features are important in electronic displays – like those in LCD TVs, e-readers and smartphones. Prototypes are in the works for rollable displays that will let you wad up your smartphone, stick a digital newspaper in your pocket or wrap a mini-computer around your wrist like a watch.

All these devices are currently made in “top-down” processes – which carve objects with nano-features out of larger materials. Adapted from the field of conventional electronics, the processes are well established and capable of mass production. But, they require pricey machinery and materials and leave behind toxic byproducts that are bad for the Desert & Water Research.

In contrast, Prof. Jelinek’s gold-based process is “bottom-up,” meaning it builds objects with nano-features piece-by-piece. The process is natural and quite simple – a high school student could do it, says Prof. Jelinek. But it is also kind of magical, like a modern-day form of alchemy.

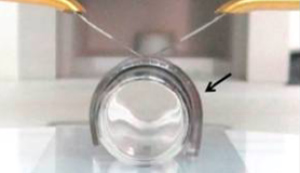

It works like this. Gold-containing molecules are dissolved in water to create a solution. Glass, plastic or polymer materials are then submerged in the solution. Wherever chemical structures called “amino groups” are present on the material – be it flat, curved or complex and 3-D – a nano-structured gold film begins to spontaneously crystalize. (A force akin to static electricity attracts and sticks the gold from the solution to amino groups.) Conveniently, amino groups naturally appear on many plastics or can be easily produced with very basic chemistry.

After a few hours or a couple days – depending on how thick you want the film to be – the material is removed from the solution, now coated with a gold film that follows whatever nano-pattern was formed by the amino groups.

The gold film conducts electricity and is see-through, allowing it to act, for example, as a circuit in devices that convert light into electricity (such as solar panels) or vice versa (as in electronic displays).

Like traditional top-down processes, Prof. Jelinek’s gold-coating process works on metals, glasses, plastics and polymers used to make conventional 2-D electronic devices and circuits. But unlike traditional processes, it works just as well on wrinkled or bent surfaces, which are the bread and butter of flexible electronics.

Significantly, Prof. Jelinek’s technology does not require sophisticated equipment, uses cheap materials and is eco-friendly.

He thinks the process could be relatively easily adapted for industrial production, bringing down the price and expanding the applications for flexible electronics. The biggest challenges are those at the heart of flexible electronics: transparency and flexibility.

The gold film has an amber hue that leads to opaqueness when it gets too thick. And Prof. Jelinek has yet to make the film flexible enough to retain good conductivity after continuous bending. Here, though, the film’s tubular nanostructure is a promising advantage.

Scientists who are familiar with the electronics industry agree that Jelinek’s process has real potential. “Professor Jelinek’s technology combines low cost and high-performance,” says Prof. Zeev Zalevsky, the head of the electro-optics study program and the director of the Nano Photonics Center at the Institute of Nanotechnology and Advanced Materials, both at Bar-Ilan University. “In my opinion, the process he developed could be very useful in wide variety of commercial fields in the near future. The challenge for all nanotechnologies, of course, is to scale up.”

To this end, Prof. Jelinek is working with BG Negev, Ben-Gurion University’s technology transfer company, which brings promising scientific innovations to market. In the meantime, he is trying to demonstrate the process’ versatility, by gold-coating different materials and creating more complicated electrical patterns and circuits.