Olives: For Food, Biodiesel, Ethanol and Medicine

Olives: For Food, Biodiesel, Ethanol and Medicine

April 7, 2011

Think of that thing in the picture as an MRI for vegetable matter.

Professor Zeev Weisman and a team of researchers at Ben-Gurion University of the Negev (BGU) have adopted a low-power nuclear magnetic resonance device (NMR) along with predictive analysis software to scan olives, castor pods and pomegranate seeds to help fuel makers and chemical companies determine the optimal strains for commercial production. The system qualitatively and quantitatively estimates the oil content and cellulosic matter of a strain of olives.

Soon, the NMR and the software — similar to emerging technology at other labs around the world — will be able to determine the amount of phenols and antioxidants in the flesh, stones and waste water in olive residue. These chemical ‘diamonds’ could then be sold to pharmaceutical or cosmetic companies.

The key is speed. Determining the lipid (or fatty acid and oil) content of a strain of olives takes 16 seconds with NMR, he said. Conventional methods — which involve crushing olives and mixing the results in solvents — take at least 24 hours.

Thousands of strains of olives exist, so being able to quickly narrow down the choices to the few best varieties is helpful. A complete genome and a commercial analysis of a strain can be accomplished in a few weeks. Conventional methods to determine the genome would require months of work.

“We are looking for the maximum amount of energy to know, without extraction, the physical properties of the fuels,” Weisman said.

And olives, it turns out, could become an interesting feedstock in certain parts of the world. When olives get pressed, only around 21 percent of the total mass ends up in jugs of olive oil.

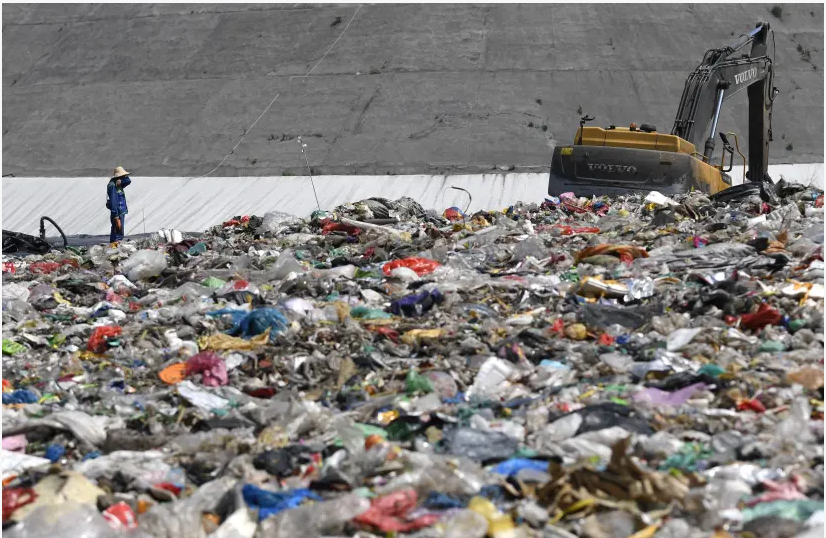

The remainder gets turned into pomace, a waste product. Often, it just gets reformed into simulated fire logs or sits in large piles at processing plants. Pomace also contains chemicals that are toxic to soil: The Israeli government has begun to regulate how it can be disposed.

Approximately 5 percent to 7 percent of the total olive mass, however, can be converted to biodiesel. The olive stone can also be converted into cellulosic ethanol. In other words, two fuels can be made from one feedstock.

“[The olive stone] contains more energy than corn,” he said. “The waste material is a gold mine.”

Approximately 15 percent to 20 percent of the olive crop also falls on the ground during harvesting. It can’t be used to press extra virgin olive oil. As fuel, however, the errant fruit on the ground still has value.

Besides analyzing the total mass of commercially interesting materials in the feedstock, the NMR can also estimate the physical properties of the materials. Certain strains of castor, for instance, can produce an oil with a low viscosity value that could be mixed into B25 biodiesel, or diesel with 25 percent of the content coming from biological matter. Unfortunately, the oil also cannot tolerate the high temperatures required in the distillation process, so as a practical matter, it can only be used to make B10 biodiesel.

So far, the NMR analysis and predictive software have proved to be relatively accurate, Weisman said. In one instance, the team found a castor strain that could be used to make B20 biodiesel. Subsequent real-world tests confirmed the results.

“If you have a viscous oil, you will get a butter in your engine,” he explained. “We can increase the income of the crushers by 20 percent.”

The oil from pomegranate seeds, he added, will not be used for fuel. The seeds don’t produce much. However, some researchers believe the seeds have therapeutic properties that may delay the onset of Alzheimer’s disease.